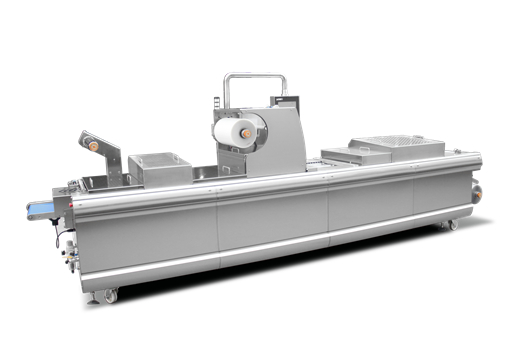

Ultrasonic tube sealer

Ultrasonic tube sealer is a thermoforming packaging machine. For specifications and certain material types, it is heated in an oven to a high enough temperature to stretch it into the mold or on the mold, and then cool to the final shape. Its simplified version is vacuum forming.

Ultrasonic tube sealer Heat a roll of multi-layer co-extruded plastic film to the bottom of the package. It integrates packaging molding, loading area, automatic liquid filling, vacuum sealing, printing and trimming. It reduces the risk of exposure to unsanitary sources.

• UtienPack products - the molding room adopts a 4-way air extraction system, which has fast molding efficiency and good stability.

• The sealing heating plate has 8 Airtac cylinders and positioners to ensure vertical sealing of the heating plate, smooth sealing, clear embossing, no skew, good sealing effect, high packaging efficiency, and no leakage after sterilization.

• The forming chamber, the vacuum sealing chamber and the cylinder lifting mechanism adopt the principle of triangular lever, which has a self-locking function to ensure stable lifting.

• The equipment is equipped with an automatic alarm function. Each part is equipped with inductive switches, which can automatically alarm and shut down. The man-machine interface can display and analyze the cause of the failure, which is convenient for engineers to maintain.

• The drying and dehumidifying system is specially designed for the electrical control system, which effectively guarantees the normal operation of the equipment, and is especially suitable for rainy areas.

English

>

English

>

Russian

Russian

French

French

Spanish

Spanish

Arabic

Arabic